Prodevco Robotic Solution Plasma PCR31

REQUEST QUOTE

Prodevco Robotic Solution Plasma PCR31

Prodevco PCR31 offers you the capability of a beam coping machine while being able to process plates in the same working space.

The NEW PCR31 Features Multiple Options at the same time as being Compact. This Robust and Easy-to-use machine automates all cutting operations typically performed on structural steel.

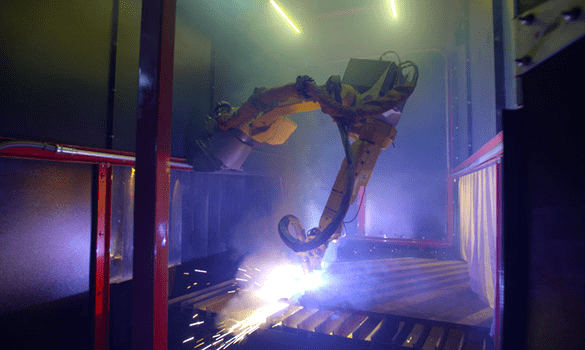

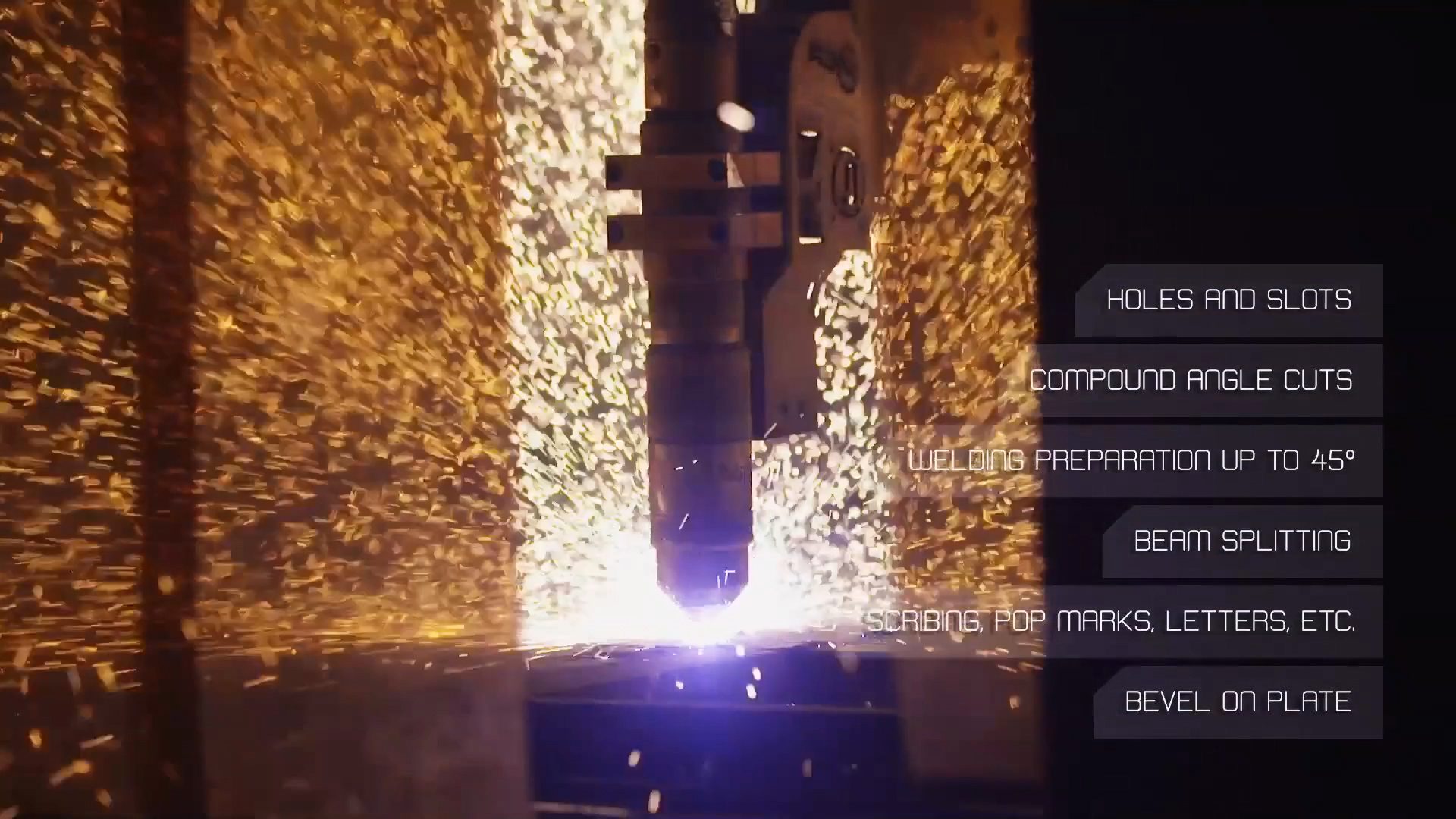

The PCR31 coping machine cuts notches, holes and weld preps, it splits beams, and scribes and marks on up to 3 faces H-beams, channels, angles, HSS and plates. Using the Hypertherm plasma cutter delivers time-saving and cost-saving structural steel shapes.

The PCR31 can process plate up to 60-inches wide, with bevelling capability. Integrated torch height control keeps control of plasma cutting machine tip to plate distance at the optimum value. Automatic torch calibration ensures the precision of bevel cut.

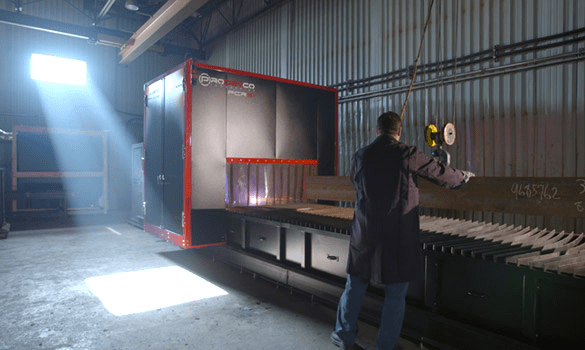

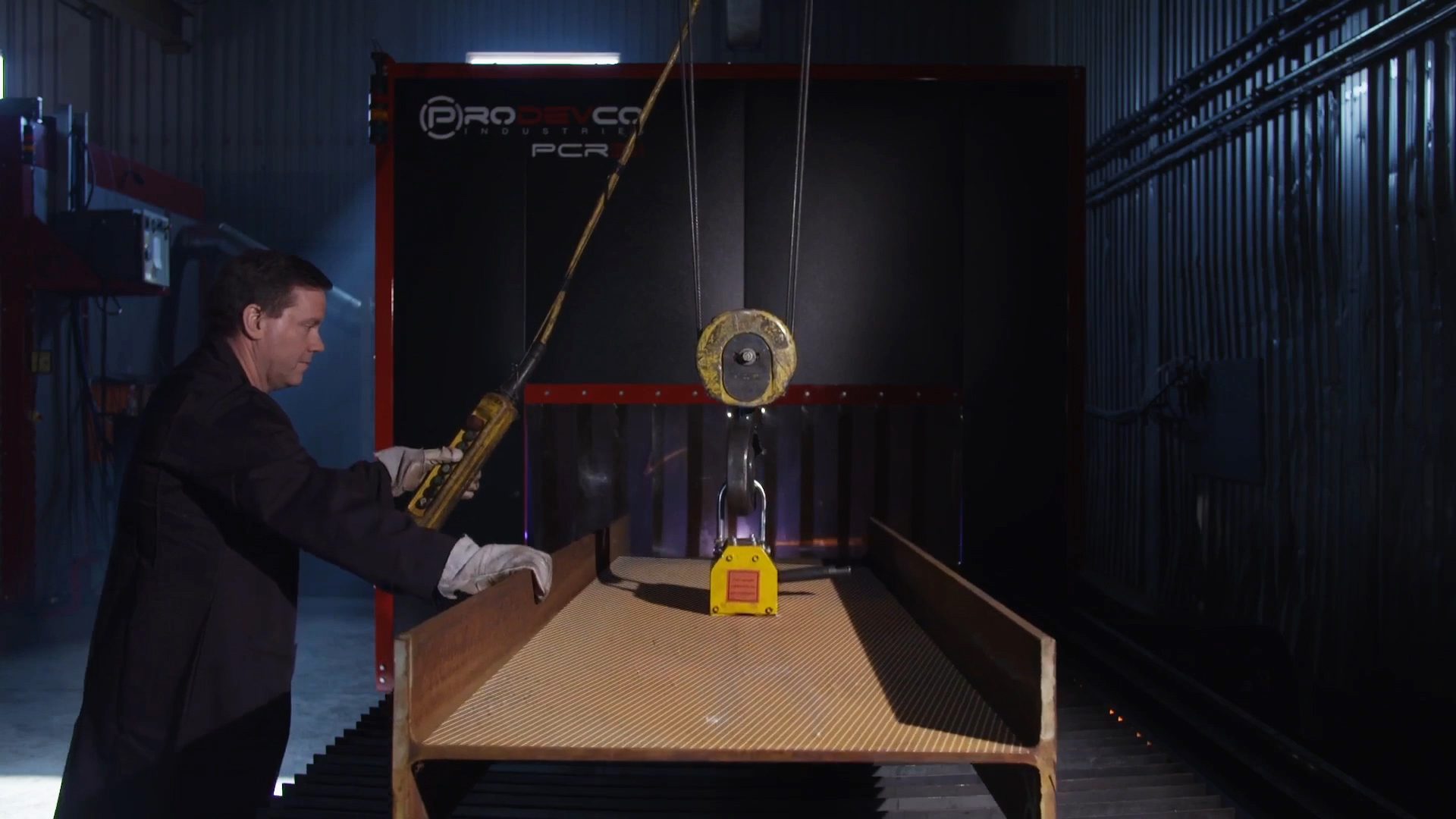

Productivity is one of the primary goal for Prodevco. The design of the PCR31 allows you to save time by accommodating loading and unloading your part while the system is working. By eliminating material handling downtime between operations, our plasma cutting machine is able to produce completely finished pieces at the lowest manufacturing cost.

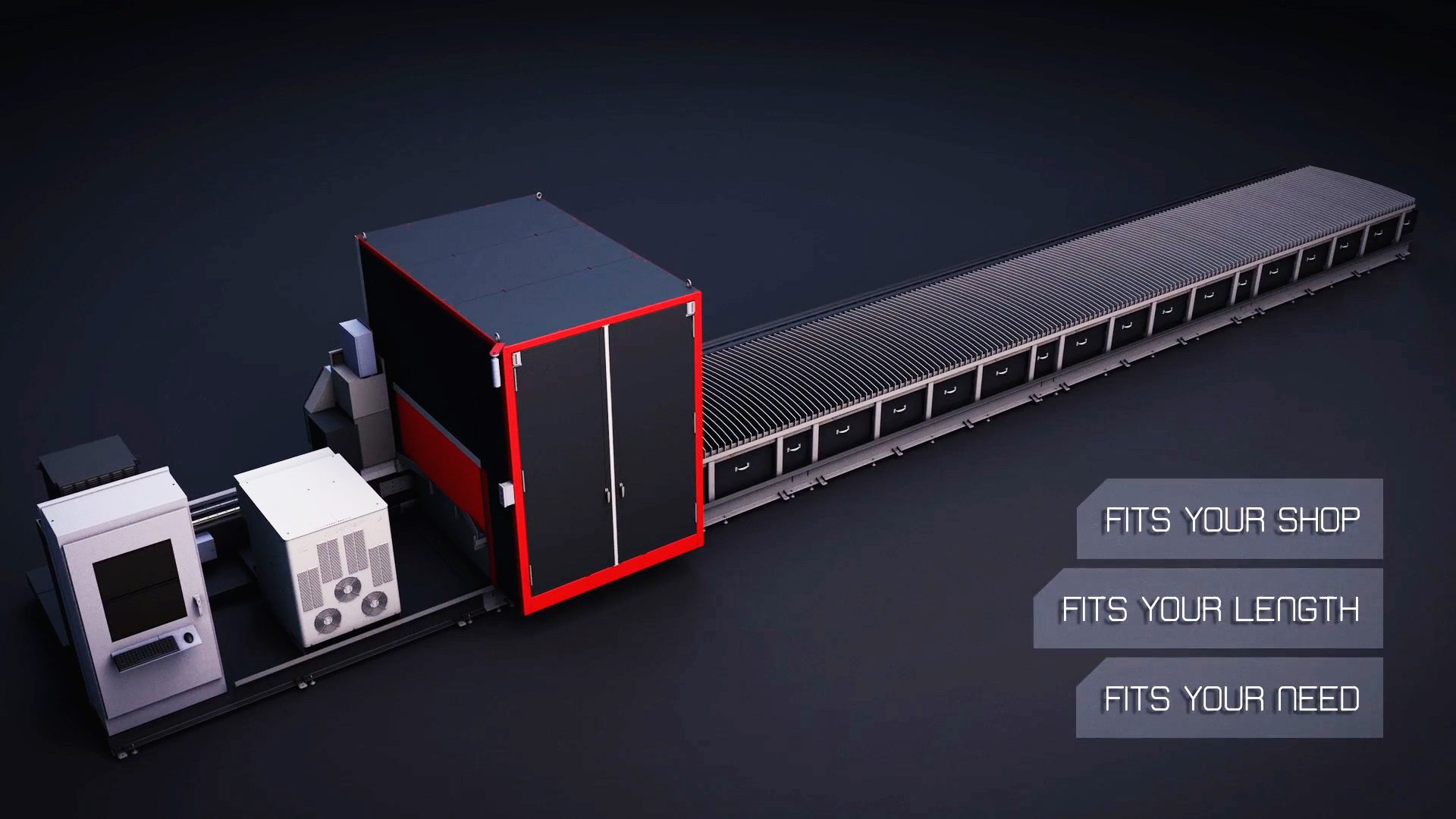

The PCR31 is available in several size configurations to accommodate your production needs and fit within your space constraints.

Our operation console is designed with simplicity in mind. Most of the information is presented graphically, reducing the training required to operate the machine.

More precise than traditional measuring methods, it avoids damage from collisions with unexpected beam profiles as well as issues with debris in the plasma torch obtained through physical probing.

World-class third-party suppliers and stringent design criteria provide a durable plasma cutting platform with very little maintenance necessary.

The measuring system ensures fast and accurate measurements and allows the processing of bent and imperfect materials. The PCR31 automatically adjusts cut trajectories to produce exact part dimensions as required in the drawings and compensates, as needed based on real material dimensions fed into the system.

The PCR31 steel coping system can process DSTV files directly from design drawing packages such as Tekla, XSteel, Design Data SDS/2, Graitec Advance Design, etc. It also allows the modification of parts directly from the machine interface.