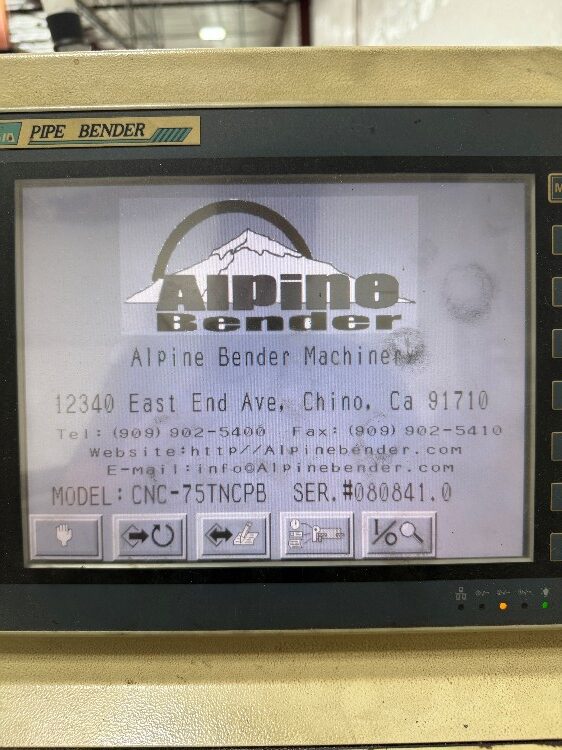

USED – ALPINE TUBE BENDER

$49,000.00

USED – ALPINE TUBE BENDER

Model: AB75NC-PB

Year: 2008

SPECIFICATIONS:

| NC-Numerical Control, P-Plane of bend, B – Bending | Base on 1.5DR | ||

| SPECIFICATION | UNIT | AB75NC-PB | (INCH) |

| Bending Capacity / Round Tube / Mild Steel (S=40kgf/m㎡) | In | 3″x0.118 | 76.2×3.0 |

| Bending Capacity / Round Tube / Non-Ferrous (S=25kgf/m㎡) | In | 3″x0.197 | 76.2×5.0 |

| Bending Capacity / Round Tube / Stainless (S=60kgf/m㎡) | In | 3″x0.071 | 76.2×1.8 |

| Bending Capacity / Square Tube / Mild Steel (S=40kgf/m㎡) | In | 2″x0.118 | 50×3.0 |

| Bending Capacity / Solid Bar / Mild Steel (S=40kgf/m㎡) | In | 1.5 | 38.1 |

| Max. Bending Radius | In | 1.57″x9.84″ | 40~250 |

| Max. Bending Angle | Degree | 190 | 190 |

| Max. Length over Mandrel | In | 94.48″ | 2400 |

| Working Height | In | 39.3″ | 1000 |

| Tooling Center Line Height | In | 2″ | 50 |

| DOB (Bending) Speed | deg / sec | 50 | 50 |

| Accuracy of DOB (Bending) | Degree | ±0.15 | ±0.15 |

| P.O.B.Speed | deg / sec | 160 | 160 |

| Accuracy Of P.O.B. | Degree | ±0.1 | ±0.1 |

| Total Power | Kw | 8 | 8.0 |

| Max. Pressure | Psi | 2,489 | 175 |

| Hydraulic Tank Capacity | Liter | 150 | 150 |

| Machine Height | In | 47.2″ | 1200 |

| Machine Width | In | 47.2″ | 1200 |

| Machine Length | In | 169.3″ | 4300 |

| Machine Weight | lbs | 5000 | 2280 kg |

Standard Equipment ~

- 0″ OD capacity – Two Axis NC Bender

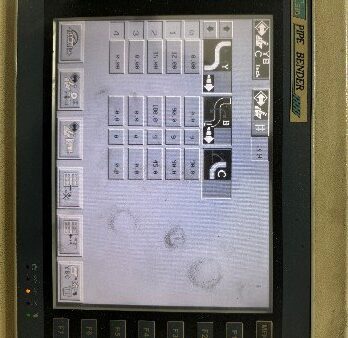

- PLC Based with LCD Touch Screen B/W Controller

- Single Stack

- Right Hand Bending

- Bend (C) Axis is driven by Hydraulic system

- Rotation (B) Axis is driven by Servo motor – Mitsubishi

- Feeding (Y) Axis’s is manual operated with 8 adjustable DBB stops

- Pressure Die Assist – Hydraulic with Flow control

- Program Storage: 8 Bends on each program / up to 100 sets of program memory

- One Shot Slide way Lubrication for bend arm to reduce maintenance time

- Air Cooling System

- Foot Pedal Cycle Start

- Adjustable Wiper Die Holder

- 3 Mandrel Rods

- User Manual and Technical Document in English

- Tool Box includes essential tooling for Adjusting and Maintenance

- Electricity : AS REQUIRED (3 phase 240V)

Included:

AMRU – Anticipate Mandrel Retract Unit

AML ready – Pre-wired for Auto Mandrel Lubrication (No tank & pump)

Safety Equipment

CE ready safety mat CONNECTION only – For OSHA requirement

Safety Mat – 3′ x 3′