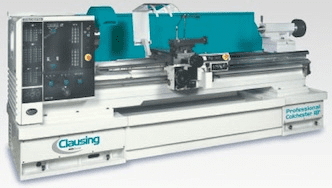

Clausing Industrial Variable Speed Lathe

REQUEST QUOTE

Clausing Industrial Variable Speed Lathe

13″ & 15″ Diameter Swing, Variable Speed

Standard Features…

- State-of-the-art AC Spindle Drive features surface mount technology to give compact size and high reliability

- Interlocked end guard door for easy access for maintenance and changing end train gears

- Faster thread cutting – Reversal of the Leadscrew with the spindle running at low speed

- An easy-to-read index plate, makes it simple to select the proper feed or threads

- Three headstock gear ranges a wide spread of constant power – 33 to 1 – better than most CNC lathes

- Infinitely variable spindle speeds displayed on headstock

- Electromagnetic spindle brake

- Spindle bearings, gears and shafts are lubricated by a forced lubrication system

- Precision tapered roller spindle bearings

- Chuck guard with limit switch

- Carriage ways coated with “Moglice” PTFE for minimal bedwear and longer machine life

- Saddle Mounted Chip Guard and Full Rear Splash Guard

- Extra Wide Heavy-duty Cast Iron Bed with triangular webs for torsional stiffness and excellent chip clearance

- Heavy Duty Tailstock with extra heavy-duty quill

- Single piece leadscrew cover protects leadscrew from chips

- Large capacity rollout chip bin for easy chip disposal

- All bedways are induction hardened and precision ground

- Heavyweight cast iron bases provide the maximum support for the bed combined with sloping top surfaces to prevent the accumulation of coolant

18″ & 21″ Diameter Swing, Variable Speed

Standard Features…

- State-of-the-art AC Spindle Drive features surface mount technology to give compact size and high reliability

- Interlocked end guard door for easy access for maintenance and changing end train gears

- Faster thread cutting – Reversal of the Leadscrew with the spindle running at low speed

- An easy-to-read index plate makes it simple to select the proper feed or threads

- Three headstock gear ranges a wide spread of constant power – 33 to 1 – better than most CNC lathes

- Infinitely variable spindle speeds displayed on headstock

- Electromagnetic spindle brake

- Spindle bearings, gears and shafts are lubricated by a forced lubricationsystem

- Precision Gamet tapered roller spindle bearings

- Chuck guard with limit switch

- Carriage ways coated with “Moglice” PTFE for minimal bedwear and longer machine life

- Saddle Mounted Chip Guard and Full Rear Splash Guard

- Extra Wide Heavy-duty Cast Iron Bed with triangular webs for torsional stiffness and excellent chip clearance

- 2 axis rapid traverse available from one lever mounted on saddle

- Heavy duty tailstock with extra heavy-duty quill

- Single piece leadscrew cover protects leadscrew from chips

- Large capacity rollout chip bin for easy chip disposal

- All bedways are induction hardened and precision ground

- Heavyweight cast iron bases provide the maximum support for the bed combined with sloping top surfaces to prevent the accumulation of coolant