AIM T-Welder

REQUEST QUOTE

AIM T-Welder

AccuForm T-Welder (cross Wire welder) TWx

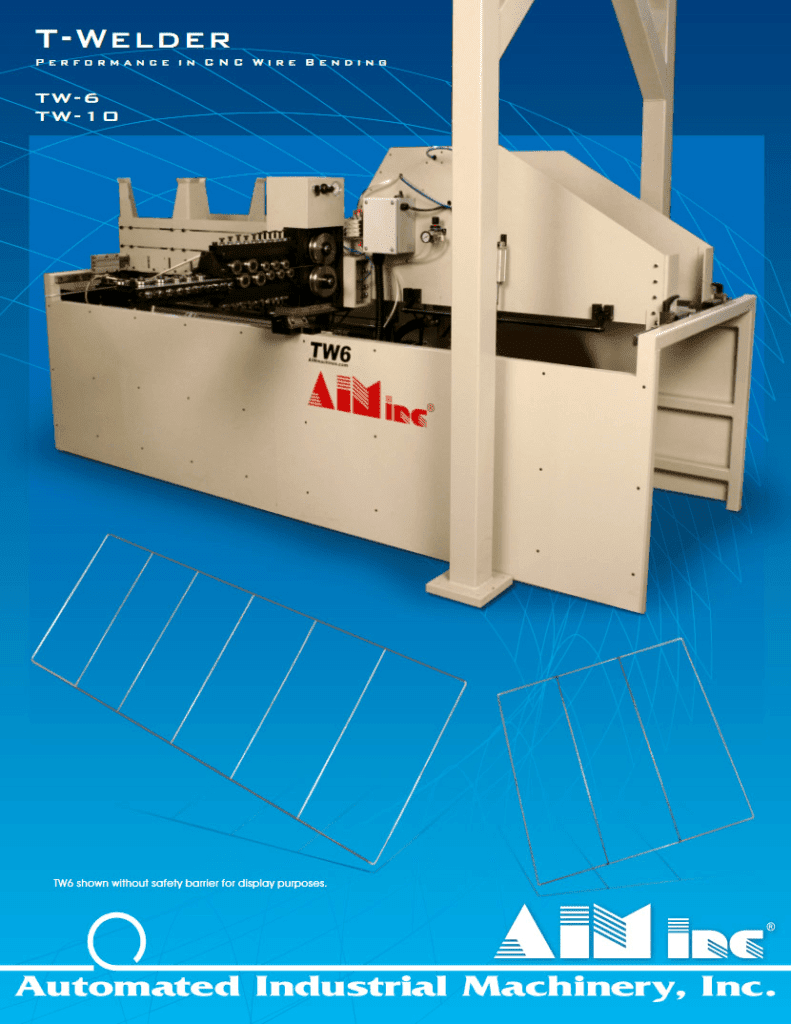

AIM T-Welder models are organized by wire size/capacity, as shown below:

| Model # | Metric (mm.) | S.A.E. (inch) |

| TW6 / TW6a | 2.0 – 6.35 | 0.079” – 0.250” |

| TW10 / TW10a | 4.0 – 10.0 | 0.157” – 0.394” |

Each AccuForm T-Welder Series machine currently has 2 fully programmable motion axes. These machines have a frame hopper and for the cross wires, they take wire directly from coil, straighten it, and cut it to manufacture T-Welded frames (also called cross wire welded frames) used for filter, refrigerator, shelving, store fixture, display, oven or grill frames to name a few.

These products can be designed with the use of AIM’s exclusive software package. SmartEditor® which provides flexibility and simplicity in setup. Programming is quick and easy. All you need is to enter the cross wire length and the location(s) of the T-welds and begin production!

AIM uses the world’s preeminent servo system. The smallest wire feeder resolution is 45 encoder pulses per millimeter and the resolution of the carriage is 225 encoder pulses per mm. The published servo controller accuracy is ±1 pulse, and the length accuracy is ±0.25 millimeters (±0.0095″). This accuracy supplied allows wire and tooling tolerance calculation and points out the wire inconsistency effect. The better the wire supplied, the better the output product will be. Accuracy and repeatability of AIM machines are exceptional.

Parabolic and S-curve positioning profiles give smoother acceleration and deceleration minimizing shape distortion while achieving higher speeds at minimum possible power usage. The standard models grant to the AIM equipment the title of the highest working speeds in the market.

Using V-groove rollers, you can run more than one wire diameter per groove and by using two V-grooves per roller, wire capacity doubles. Power transmission is through high torque, precision drive belts and in some cases, high precision planetary gearboxes; NO adjustments needed.

Quick and easy wire diameter changeover is a standard system feature.

Double action pneumatic cutter for strong and fast cuts: All of the cylinders installed in AIM machines are double acting, providing fast and powerful motion for the extra heavy-duty machine operation, including cutting the wire. AIM machines incorporate simple design and easy access with worldwide part availability. Simplicity, robustness, functionality and speed are the basic engineering principals AIM adheres to.

Easy tooling changeover makes the machine setup quick and efficient. Clear drawings supplied upon request for a nominal fee, easily allow AIM customers to manufacture their own tools, such as cutters, rollers, bending pins, grippers and all other consumable items. Couple this convenience with excellent customer support reputation and spare parts delivery, AIM provides the best CNC bending machine value in the world.

AIM uses robust engineering for long life and low maintenance. Using enclosed type brushless servomotors along with highest precision planetary gearboxes provides the best machine operation. All critical components have over-temperature, over-current, and over-voltage protection installed. All bearings used are oversized and double-sealed for longer life expectancy and lower maintenance. The design of the AccuForm machines provides for maximum safety standards and life expectancy factors. AccuForm T-Welder machines come backed by a one-year parts and labor limited warranty. Excluded are the wear parts that “touch” the wire (such us cutters, rollers, welding inserts etc.), although all of these wear parts are made from the hardest tool steels and heat-treated to Rockwell scale 55°-65° degrees.

Parts purchased from other manufacturers carry their own OEM-warranty. For example, the precision gearboxes made by ALPHA®, the world’s largest high-precision gearbox manufacturer, have a 5-year warranty. AIM always installs the best quality parts available and never sacrifices quality for price. Even after the warranty expires and within common sense rules, AIM provides technical support free of charge for the first owner.

The operating system used is currently Windows® XP Professional. Video conferencing is available as an option. Besides for support communications you can also use Video Teleconferencing over your existing LAN through the Internet or you can just watch your equipment performing from the convenience of your office PC.

Statistical analysis with the touch of a button – a standard SmartEditor® feature! Let the computer figure it out: including production rates, time, shifts, days, wire needed, wire spools required, including spool changeover time. All the factors involved are parametric and are customizable to fit every need. Using the SmartEditor® Office version (available upon customer request), you can use the “EZ-Quote” analysis from your office PC. Production statistics can be saved automatically, locally on the machine or on a network computer for review and analysis frequently needed by ISO 9000 quality analysis programs or the customer’s lean manufacturing system.

TWx Machine Description

The TW-x line of equipment is designed with the old four-slide technology in mind but without the time consuming intricate setups, costly tooling, and the need for an expert operator. The TW in the model number stands for “T-Welder” which means the machine has Cross wire welding capability.

The user programs the straight wire length and the intervals/distances that need to be welded. The only limitation on the number of cross wires is the size of the frame. The cross wire feeder automatically feeds the wire through a straightener and cuts the wire to user pre-defined lengths. A “smart” hopper mechanism places the straight wire pieces direct into the pre-fed frame and the machine welds it. An automatic gripper, after the part is complete, ejects the finished part to a completed part container.

The TW-x machine has five (5) independent systems.

1) The cross wire Feeder coordinate

2) The frame Hopper coordinate

3) The frame carriage system

4) The Welding system

5) The Eject part coordinate

Since all coordinate systems operate independently, they can all work simultaneously, synchronized by the Frame Hopper coordinate. Even with the complicated TW configuration, the AIM SmartEditor® software generates the algorithms needed by the machine controller automatically. The AIM TW machine has built-in algorithms that build the complex motion algorithms!

The AIM user simply enters cross wire length and welding positions that comprise the desired part and SmartEditor® does all the rest.

Cross wire feeder

The cross wire feeder is typically a straight and cut machine by itself: A coil is set on an automatic powered payoff unit which feeds the feeder mechanism with wire. The feeder mechanism, using separate velocity and position feedback, assures that the preprogrammed length is fed at the most optimized manner and delivers the cross wires to the frame carriage system for further processing.

Frame Hopper

The frame hopper can accommodate frames from our AccuForm 2D machines or it could be used as a standalone system. Adjustable frame guides can accommodate various user defined frame sizes and with the help of four “dispensing fingers” can deliver the frames flat to the automated carriage.

Frame Carriage system

The frame carriage system consists of a strong pneumatic frame clamp, a solid rail transfer system and a precision planetary gear head coupled by a brushless servo motor. It assures an accurate and repeatable frame position that can deliver a consistent good quality product.

Welding System

The welding assembly consists of two heavy-duty cross wire clamps which transfer the already cut wire inside or on top of the frame and welds it. The welder can be programmed to weld each side individually or both together at the same time, speeding up the production cycle. Then it signals the Frame transfer system to continue with the next programmed step until it finishes and delivers the finished product to the part Eject system. A three phase balanced load, DC welding, mid frequency welding controller assures that all welding specifications

Part Eject System

This is a simple automation system that assures the completed part is delivered into the “collection bin”. It always waits for the Frame carriage system to signal for a completed part ready to be delivered, it “centers” the completed part and drops it to the container. All this is happening at the same time that the frame carriage system is getting a new frame from the frame hopper.

From the above description of the individual machine systems, it is obvious that for the best machine operation and optimum part delivery, all system need to work individually fast but yet coordinate with each other in order to provide the best possible output. These are the motions that are all created automatically by our proprietary software, SmartEditor®, without having the user think about it.