Saw Blades

REQUEST QUOTE

Saw Blades

Add this to your quote and Tony will contact you to ensure you get exactly what you need.

BLADE WIDTHS: 3 mm – 80 mm, 1/8″ – 3″

|

BI-ALFA COBALT

|

The bi-alfa cobalt bandsaw blade has HSS M42 cutting tips. The high wear resistance of the saw blade results from the very hard and evenly distributed carbides in the tooth tips, formed during the hardening and tempering process. The martensitic structure of the cutting tips and high cobalt cont3ent create excellent heat resistance, hardness and toughness, reducing wear rates at high sawing speeds. With a steel backing strip containing high chromium, the saw blade can withstand the considerable flexing stresses, tension, and blade-guide pressure, present in modern sawing machines.

|

|

BI-ALFA MATRIX2

|

The bi-alfa Matrix2 Band Saw Blade is bsed on cutting tips with a low carbide martensitic structure ensuring maximum toughness. Wear resistance at high temperatures is achieved by a high cobalt content. A precisely controlled heat treatment process optimizes hardness and toughness for interrupted cutting applications, particularly hollow sections.

|

|

BI-ALFA MASTER

|

The bi-alfa Master Band Saw Blade harnesses the benefits of “triple chip” tooth geometry, widely recognized as the optimum form for production sawing. The teeth are CBN precision ground to form a chamfered high tooth (A) and a pair of lower finishing teen (B & C). Cutting faces are ground parallel to the back edge ensuring absolutely straight cutting. The M42 tooth tips have a height difference calculated to suit the typical chip load characteristics of each blade width/pitch combination. High cutting rates can be achieved without compromising blade life or cut finish.

|

|

BI-ALFA COBALT RP

|

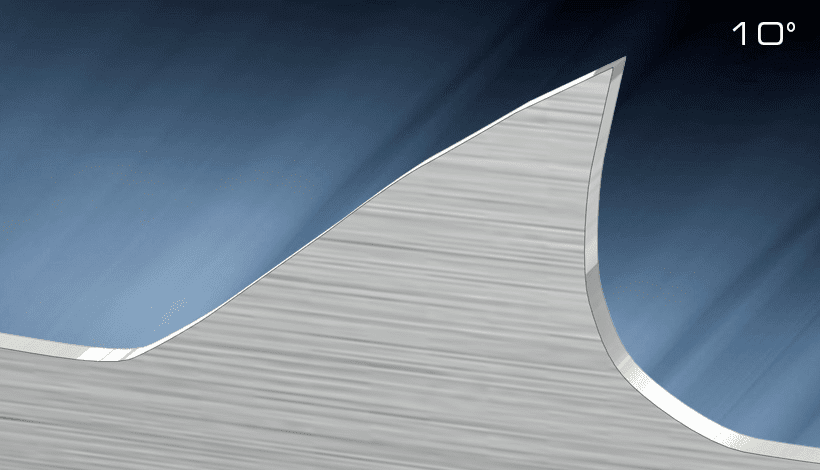

Bi-alfa RP is a new extension of the highly successful bi-alfa M42. The tooth shape is milled with a cutting angle of 16° without any loss in tooth strength. This aggressive tooth form is ideal for hard materials, improving chip flow and blade life.

|

|

BI-ALFA RP MASTER

|

bi-alfa RP Master combines the precision sawing capabilities of the Master blade with the aggressive RP 16° cutting face. The CBN ground finish linked to triple chip tooth geometry, guarantees fast square sawing, and excellent cut finish even on the most difficult materials.

|

|

HM-TITAN

|

The HM-Titan carbide tipped band saw blade, is the ideal choice for the highest possible cutting rates on abrasive and hard metals and composites. MHM-Titan has a new tooth geometry, which limits tooth load and reduces the incidence of tip loss. This features, combined with the fatigue resistant alloyed steel backing, ensures extensive blade life. The abrasion resistance of the diamond ground and polished tungsten carbide tips, provide the only viable sawing solution for high silicon aluminum alloys and epoxy glass and graphite composites.

|

|

ROENTGEN GRIT

|

grit edged band saw blades are designed to cut materials which will not form a chip. Multifaceted tungsten carbide grains are brazed to either a continuous or gulleted flexible steel backing. The sawing action is similar to abrasive cutting and a range of grit sizes is available to achieve the required cutting rate and finish.

|

|

RRR

|

RRR flexback carbon band saw blades have a pin-point carbide structure of 30 – 50 grains per um2, The presence of hard iron carbides produces outstanding tooth edge wear resistance, together with high flex strength in the backing steel material.

|

|

RRR-PLUS

|

RRR-PLUS hardback carbon band saw blades have a pinpoint carbide structure of 30 – 50 grains per um2 and precision milled tooth profiles. A special heat treatment process increases the tensile strength of the steel backing material and the wear resistance of the tooth edge. These features result in a premium quality, long life carbon band saw blade.

|